江苏华星东方催化剂离线再生服务自南京江北垃圾焚烧发电项目上线以来已有六年时间,期间我们本着服务匠心的精神不断对催化剂离线再生技术进行深耕及完善,研发了可移动式催化剂离线再生装置和上门再生服务。在这一领域中,我们的技术实力已得到了市场的充分认可。

The catalyst offline regeneration solution from Jiangsu Huaxing-east has run 6 years since the launch of Nanjing Jiangbei waste incineration plant. During this period, Huaxing has continuously deepened and improved the catalyst offline regeneration techniques powered by service ingenuity, and developed mobile catalyst offline regeneration equipment and on-site regeneration service. In this field, Huaxing's technical strength has been fully recognized by the market.

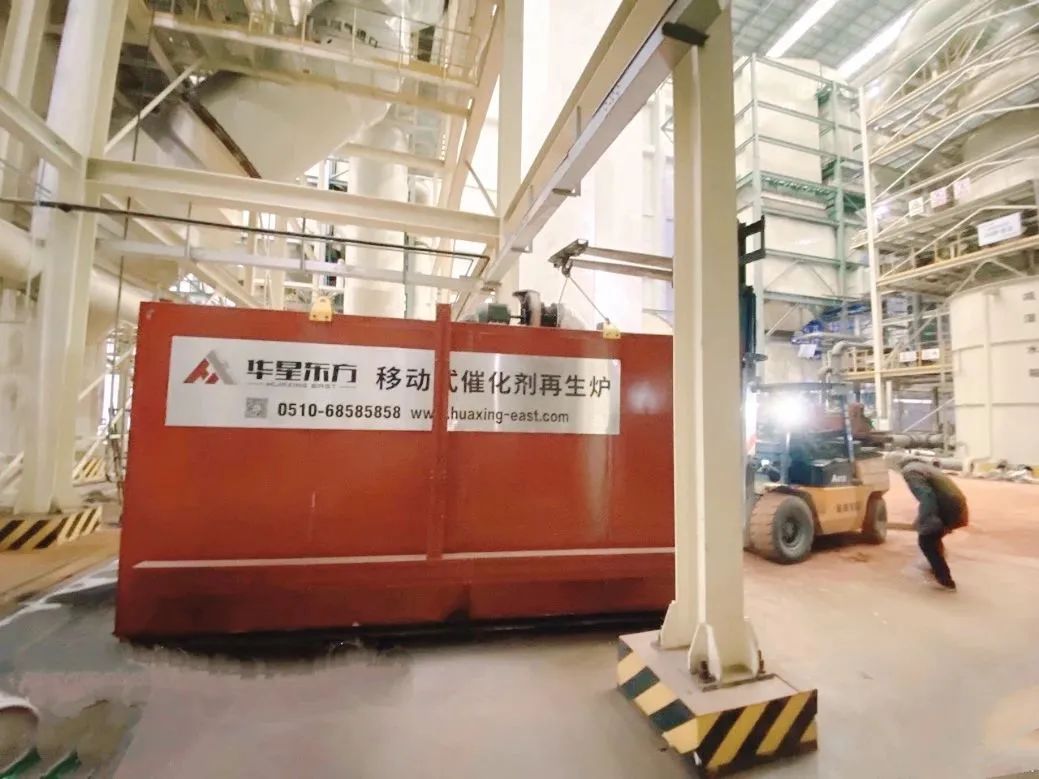

催化剂离线再生是解决因硫酸氢铵(ABS)造成中毒的催化剂可继续再生使用的技术。在台州旺能生活垃圾焚烧发电项目催化剂离线再生过程中,现场共设置2台4模块移动式再生炉,2台同时运行一次可再生8个模块。将原更换下的催化剂利用叉车搬运至催化剂离线再生炉中,根据催化剂中毒严重程度可设置再生时长,测试排气口SO2及NH3浓度,判定再生是否结束。在催化剂离线再生过程中我们同时为客户提供备用催化剂以及停炉检修的服务,方便客户可以快速起炉。(江苏华星东方1x8模块催化剂离线再生炉正在研发当中,不日便可上线投用。)

Catalyst offline regeneration is a technique to regenerate and reuse the catalyst contaminated by ammonia bisulfate (ABS).In the catalyst offline regeneration process of Taizhou Wangneng waste incineration plant, 2 of 4-module mobile regeneration devices, which can simultaneously process 8 modules, were set up on-site. The contaminated catalyst is transported to the catalyst offline regeneration furnace by forklift. The regeneration time can be set according to the severity of contamination. After the regeneration process, the concentration of SO2 and NH3 at the exhaust outlet will be tested as the proof of regeneration completion. In the process of offline catalyst regeneration, Huaxing also provides customers spare catalyst and shutdown maintenance, so that customers can start the boiler quickly. ( Jiangsu Huaxing-east's 8-module offline regeneration furnace is under development and will be put into operation shortly )

催化剂形式:波纹板式催化剂

Catalyst type: corrugated plate catalyst

催化剂模块尺寸:1839x925x1230

Catalyst module size: 1839x925x1230 mm

最高承受温度:420℃

Maximum temperature: 420 ℃

一、再生前工作设备及排气管道就位

1.Working device and exhaust pipe in place before regeneration

二、催化剂表面清理

2. Surface cleaning of catalyst module

三、催化剂进炉再生

3. Enter the regeneration furnace

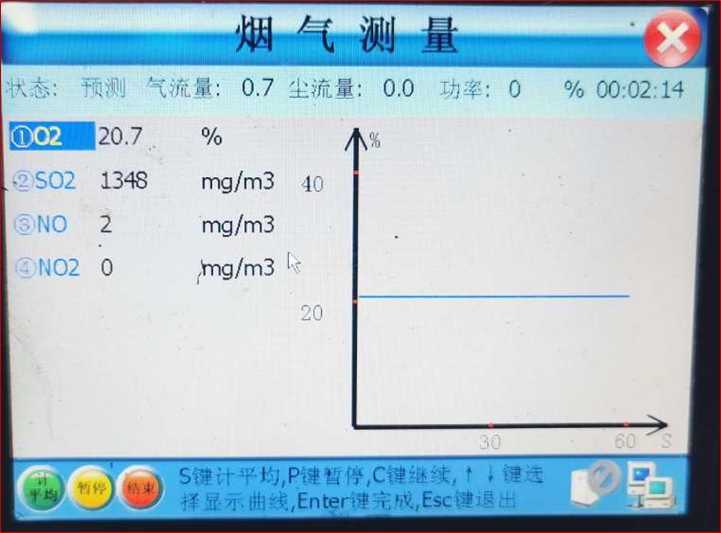

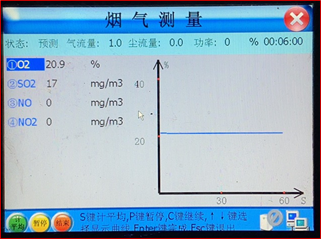

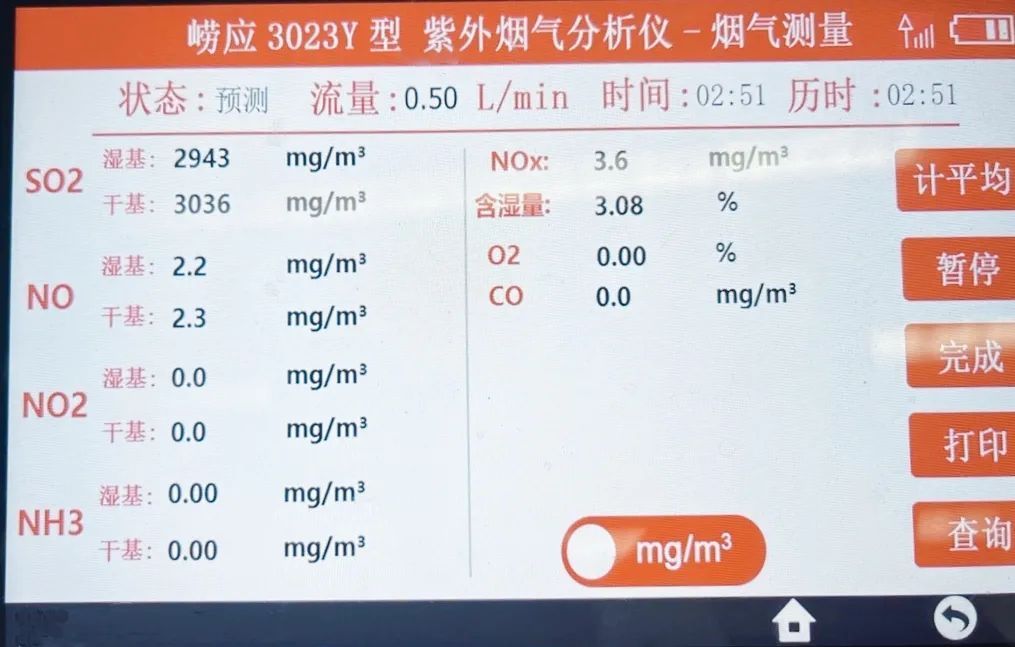

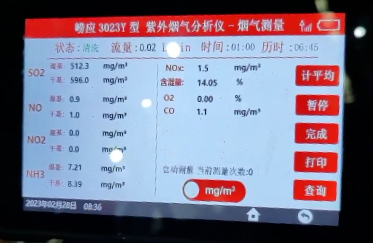

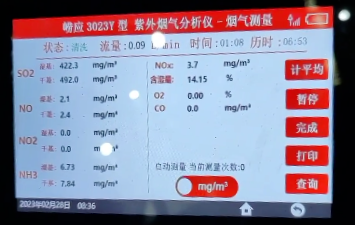

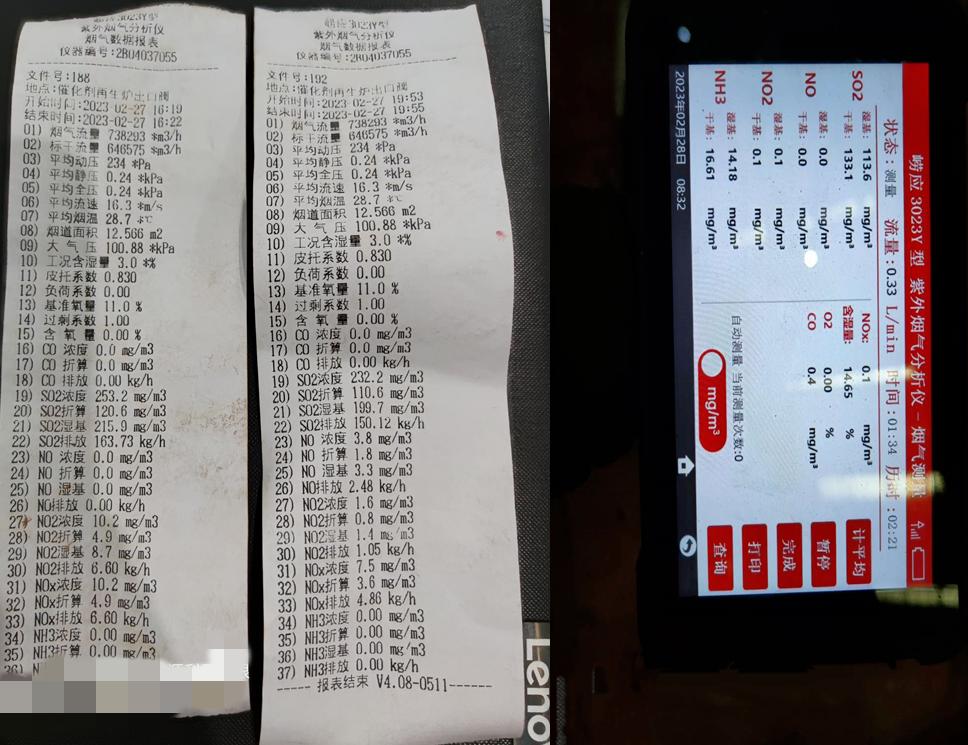

四、再生过程中催化剂排气检测

4. Exhaust detection during regeneration

五、催化剂再生完成后催化剂表面

5. Catalyst surface check after regeneration

波纹板式催化剂

Corrugated plate catalyst

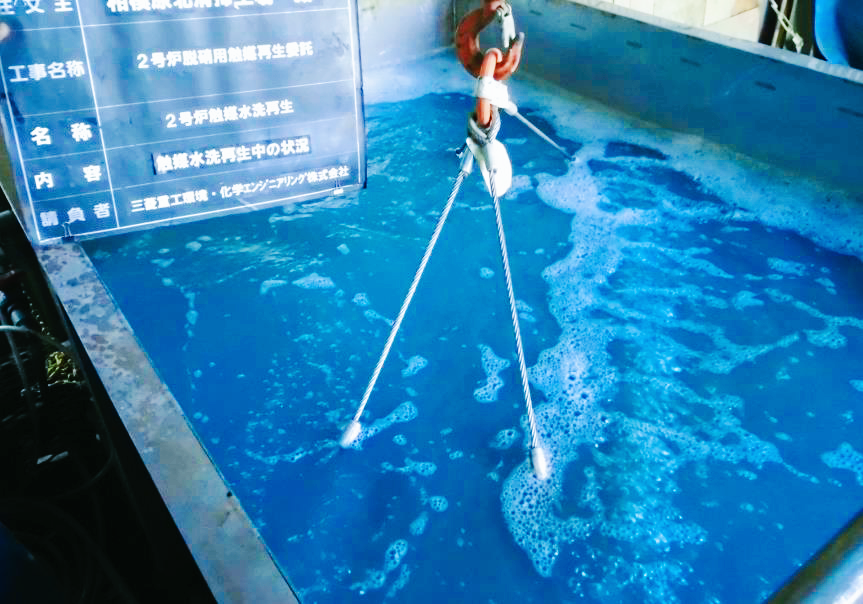

当催化剂出现化学中毒失效时我公司还可以采用催化剂离线水洗再生工艺。通过对催化剂深度清洗和活性再植入,解决碱金属、碱土金属以及重金属引起的催化剂化学失活,并赋予催化剂短期活性,满足脱硝工艺需求。

In case of chemical contamination and failure of the catalyst, Huaxing also developed offline water-washing regeneration process. The chemical deactivation of the catalyst caused by alkali metals, alkaline-earth metals and heavy metals can be solved by deep cleaning and active re-implantation, giving catalyst short-term activity to meet the demand of denitration process.

离线水洗

offline water-washing

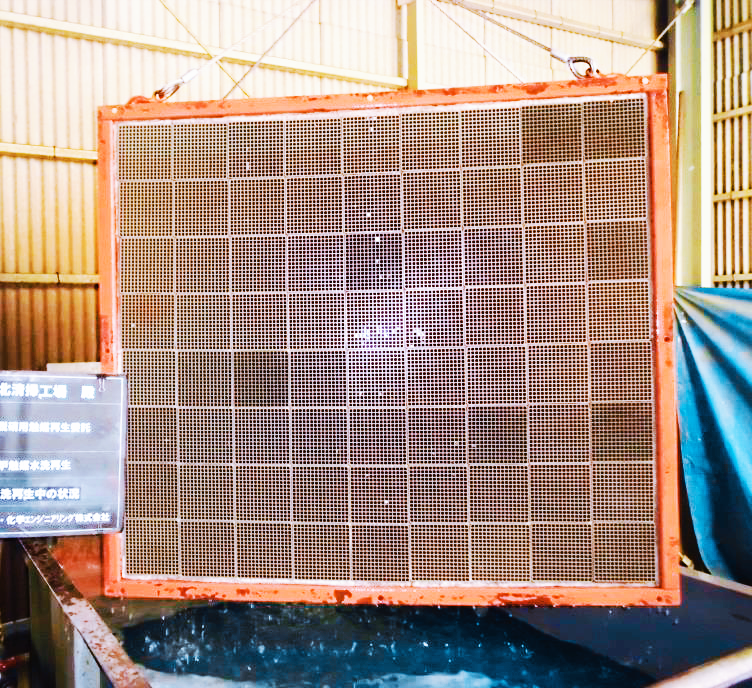

蜂窝式催化剂

Honeycomb catalyst

建德浦发生活垃圾焚烧发电项目催化剂离线再生服务

Catalyst offline regeneration service for Jiande Pufa waste incineration power plant

催化剂形式:蜂窝式催化剂

Catalyst type: honeycomb catalyst

催化剂模块尺寸:1839x925x1350

Catalyst module size: 1839x925x1350mm

最高承受温度:420℃

Maximum temperature: 420 ℃

2016年华星东方与日本三菱重工达成技术转让协议,由三菱重工向华星东方授权转让先进的超净排放烟气净化技术。日本三菱重工作为全球领先的垃圾焚烧技术公司,拥有国际领先的烟气净化技术,其中单塔双循环湿式洗涤技术,低温烟气脱硝技术,催化剂离线再生等在国际上拥有领先优势,并具有众多工程经验。华星东方先后引进日本三菱重工的湿式洗涤、低温SCR脱硝及III代低温脱硝催化剂生产制造技术(中国区域独占许可)、催化剂离线再生技术(中国区域独占许可)。主要适用于生活垃圾、危险废弃物、污泥焚烧等低温烟气环境。

In 2016, Huaxing reached a technology transfer agreement with Mitsubishi Heavy Industries (MHI) of Japan, which authorized the transfer of advanced ultra-clean emission technology of flue gas cleaning (FGC) to Huaxing. As a leading company in the field of waste incineration in the world, MHI owns advanced FGC technologies, such as single-tower dual-cycle wet scrubbing, low-temperature flue gas denitration, catalyst offline regeneration, as well as relevant engineering experiences. Huaxing has successively introduced the production and manufacturing technology of MHI's wet scrubbing, low-temperature SCR denitration, third-generation low-temperature denitration catalyst ( Exclusive license in China ), and catalyst offline regeneration ( Exclusive license in China ). These technologies are mainly applicable to flue gas generated by municipal waste, hazardous waste, and sludge incineration.

三菱重工的进口催化剂在国内也拥有众多一线项目的市场业绩,如:上海老港二期,深圳东部,北京顺义,武汉千子山一期等。江苏华星东方除了与三菱重工拥有转化技术的合作外,还作为三菱重工进口催化剂的中国地区独占代理销售其进口催化剂。

The catalyst imported from Mitsubishi Heavy Industries also have market references in many leading plants in China, such as Shanghai Laogang Phase II, Shenzhen East, Beijing Shunyi, Wuhan Qianzishan Phase I, etc. In addition to the cooperation with Mitsubishi Heavy Industries in the technology transformation, Huaxing also acts as the exclusive licensee of Mitsubishi Heavy Industries in China to sell the imported catalysts.

三菱重工环境·化学工程株式会社参观交流

Mitsubishi Heavy Industries Environment · Chemical Engineering Co., Ltd. Visiting and Meeting

江苏华星东方与三菱重工持续合作研发催化剂

Jiangsu Huaxing-east and Mitsubishi Heavy Industries continue to cooperate in the research and development of catalysts

江苏华星东方催化剂离线再生系统服务在全国业绩涵盖包括—催化剂离线原位再生系统:濮阳、青岛、西安、徐州、临沂、丽江、宜宾等多个项目。催化剂离线离位再生系统:南京、石首、平阳、宜春、丰城、福州、崇明、海盐、济宁、北京、武汉、曹妃甸、建德、安康、石家庄、台州等多个项目。

Jiangsu Huaxing-east's catalyst offline regeneration system has covered many projects nationwide including Puyang, Qingdao, Xi'an, Xuzhou, Linyi, Lijiang, Yibin, etc. Catalyst offline off-site regeneration system: Nanjing, Shishou, Pingyang, Yichun, Fengcheng, Fuzhou, Chongming, Haiyan, Jining, Beijing, Wuhan, Caofeidian, Jiande, Ankang, Shijiazhuang, Taizhou, etc.