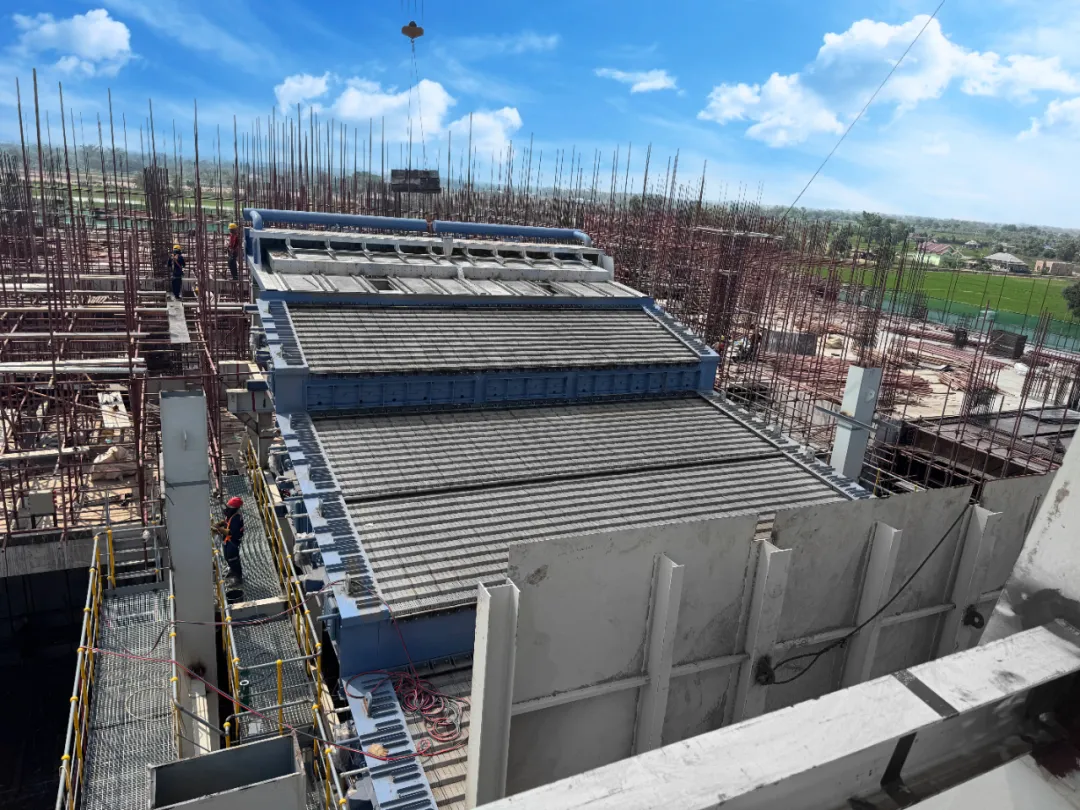

我公司承建的印度尼西亚巨港市垃圾焚烧发电项目炉排制造+烟气净化工程于2025年08月05日开工建设。

The grate manufacturing and flue-gas cleaning package for the Palembang municipal solid-waste-to-energy (WTE) project in Indonesia, undertaken by HEPT, officially broke ground on 5th. August 2025.

巨港垃圾焚烧发电项目是2018年印尼政府“总统令”下首个开工建设的垃圾焚烧发电项目,该项目设计规模日焚烧处理生活垃圾1000 吨。配置2x500t/d机械炉排炉+1x20MW凝汽式轮发电机组。烟气净化采用“SNCR炉内脱硝(尿素)+半干法[Ca(OH)2浆液]+干法[Ca(OH)2]+活性炭喷射+袋式除尘+飞灰输送存储及稳定化”的处理工艺,为我司项目供货工程。项目建成后将极大缓解巨港当地生活垃圾填埋、处置压力,年上网电量将超1.3亿千瓦时,为当地垃圾处置、环境保护与资源综合利用树立良好典范。

Initiated under Indonesia's 2018 Presidential Decree, the Palembang WTE plant is the first waste-incineration power project to start construction under that mandate. Designed to incinerate 1,000 tonnes of domestic waste per day, the plant is configured with 2 × 500 t/d mechanical grate furnaces and 1 × 20 MW condensing steam-turbine generator. The flue-gas cleaning train—supplied by HEPT—adopts "SNCR in-furnace de-NOx (urea) + semi-dry [Ca(OH)₂ slurry] + dry [Ca(OH)₂] + activated-carbon injection + bag filter + fly-ash conveying, storage & stabilisation". Upon completion, the project will markedly relieve landfill pressure in Palembang and deliver over 130 GWh of grid electricity annually, setting a benchmark for waste management, environmental protection and resource recovery in the region.

该项目炉排炉使用丹麦伟纶风冷炉排技术,由中科润宇供货,我司进行加工制造。从技术人员的精心设计,到车间内现代化的生产线高效运转,精准地切割、打磨着炉排的各个部件,从原材料的检验入库,到零部件的加工成型,再到炉排整体的组装调试,每一道工序都严格遵循着国际先进的制造标准,每一个环节都凝聚着我司员工的智慧与汗水。正是这样的精益求精,确保了每一台炉排都能达到最优的性能指标,为巨港垃圾发电项目的稳定运行提供了坚实保障。

The grate furnaces employ Denmark's Vølund air-cooled grate technology, supplied by CSET and manufactured by Huaxing Dongfang. From meticulous design by our engineers to high-efficiency operation on modern production lines—precise cutting, grinding and forming of every grate component; from incoming-material inspection to part machining, final assembly and commissioning—each step follows international advanced manufacturing standards, reflecting the wisdom and dedication of Huaxing Dongfang staff. This relentless pursuit of excellence ensures every grate achieves optimal performance, providing a solid guarantee for stable operation of the Palembang WTE plant.

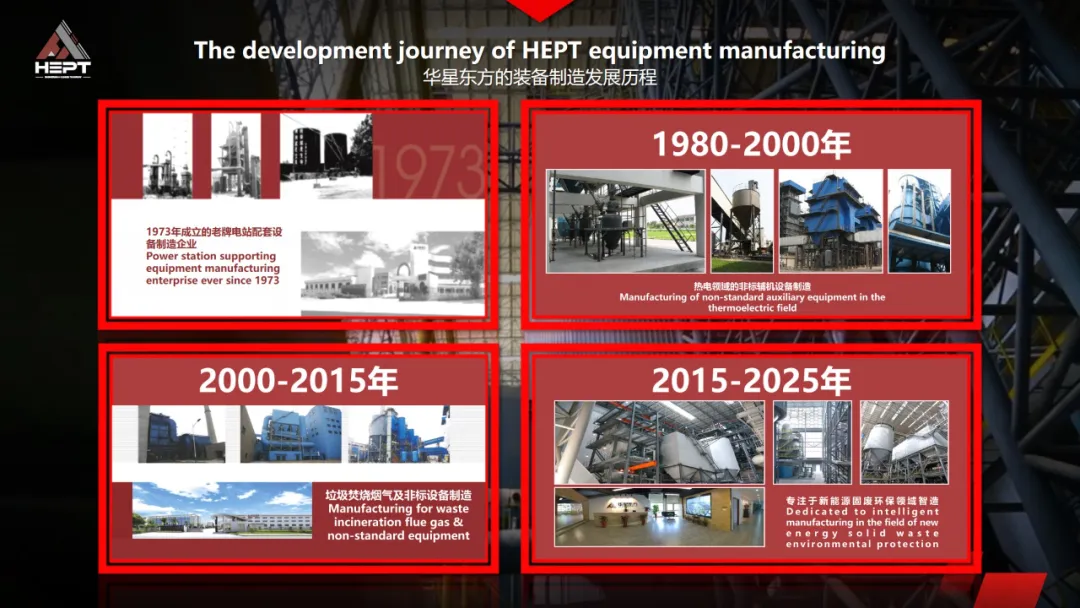

华星东方作为“业内多技术种类、高制造标准、大产能配套的国际性环保设备制造领域领军企业”,凭借卓越的制造优势与不懈的技术追求,在环保设备制造领域深耕数十年,为德国GEA、日本三菱重工、德国鲁尔、德国LAWI(水冷炉排)、伟纶、荏原、瀚蓝、中科、上海环境、绿动等众多知名企业提供高品质生产制造服务。

The grate furnaces employ Denmark's Vølund air-cooled grate technology, supplied by CSET and manufactured by Huaxing Dongfang. From meticulous design by our engineers to high-efficiency operation on modern production lines—precise cutting, grinding and forming of every grate component; from incoming-material inspection to part machining, final assembly and commissioning—each step follows international advanced manufacturing standards, reflecting the wisdom and dedication of Huaxing Dongfang staff. This relentless pursuit of excellence ensures every grate achieves optimal performance, providing a solid guarantee for stable operation of the Palembang WTE plant.

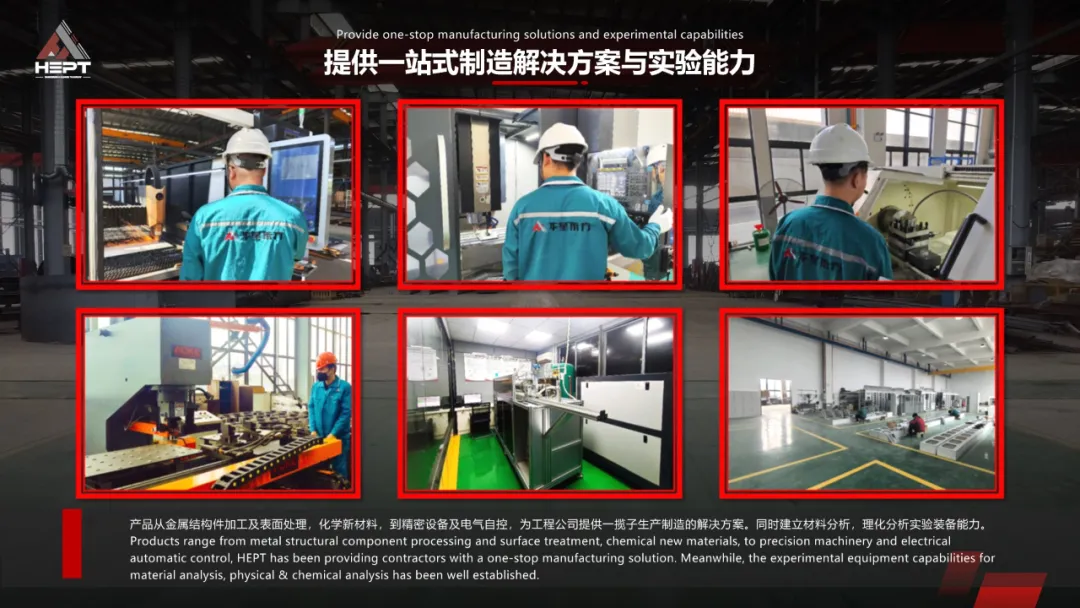

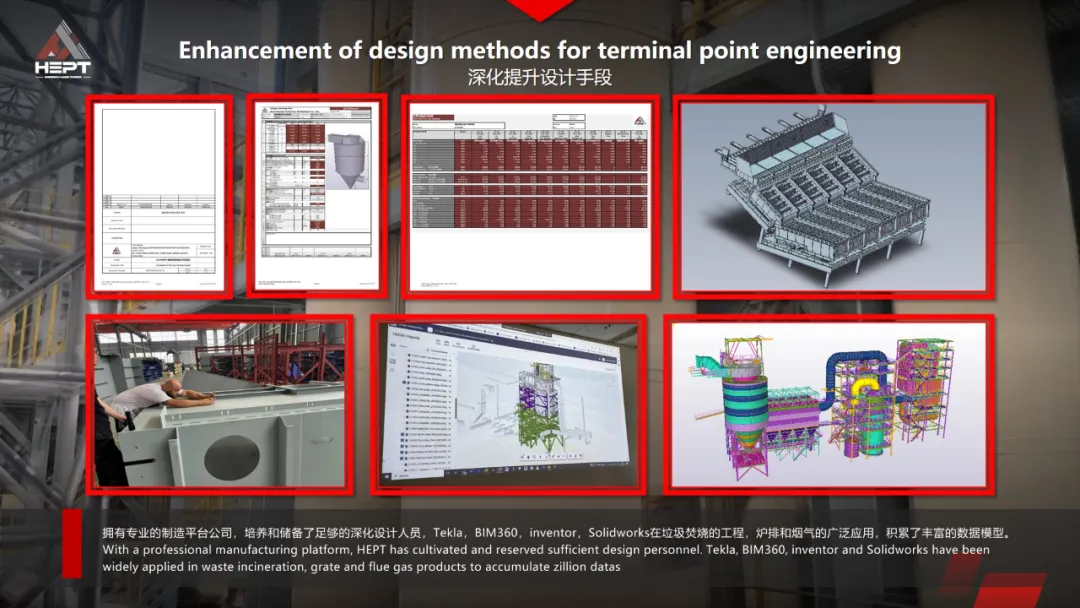

在炉排等核心设备制造方面,我们不断引进和吸收国际先进技术,将其融入自身的研发与制造体系,持续提升研发能力和制造水平。对于炉排部分精密部件的加工,公司配备了完善的数控车床,具备二次深化开发的能力。

We continuously introduce and absorb international advanced technologies, integrating them into our R&D and manufacturing systems to enhance development and production capabilities. For precision machining of grate components, the company is equipped with full CNC lathes and possesses secondary deep-development ability.

在公司下属各生产基地进行了有序分工,并在无锡工厂设置了整体自控调试平台,具备为1200吨级的焚烧炉排进行整体联动调试的能力。

Production bases under HEPT are rationally allocated; an integrated control & commissioning platform in Wuxi plant can perform full-link debugging for 1,200 t/d grate lines.

华星东方秉持“追求技术至上,品质优先”的理念,积极与各个国家和地区广泛开展产能合作,大力拓展海外市场。目前,多个炉排、烟气及配套设施制造项目已在泰国马哈沙拉堪、印尼巨港、泰国沙缴府、泰国猜纳府、广东佛山南海、内蒙古卓资、湖南常宁、四川广元、等地区落地实施。

Upholding the philosophy of "Technology Priority, Quality First ", HEPT actively cooperates worldwide and expands overseas markets. Currently, multiple grate, flue-gas and auxiliary-equipment manufacturing projects have been implemented in Mahasarakham (Thailand), Palembang (Indonesia), Sa Kaeo (Thailand), Chai Nat (Thailand), Nanhai-Foshan (Canton), Zhuozi (Inner Mongolia), Changning (Hunan), Guangyuan (Sichuan), and other regions.

我们依靠强大的产能优势和技术优势,积极布局海外版图,全力打造精品工程,树立区域绿色能源标杆项目,为全球环保事业的发展贡献着华星东方的智慧和力量。

Relying on strong production capacity and technological advantages, HEPT is strategically laying out its global footprint, creating benchmark green-energy projects and contributing HEPT's wisdom and strength to the development of environmental protection worldwide.

更多内容请点击或扫描下方!

关注我们!

For more information, please click or scan below!

Follow us!