Sailing to the sea I Huaxing east co. successfully completed the flue gas purification project of the 8MW industrial waste incineration power generation project of SCG Cement Group in Thailand

The flue gas cleaning project of the 8MW industrial waste incineration power generation project of Thailand SCG Cement Group undertaken by our company passed commissioning and acceptance on December 22, 2019.

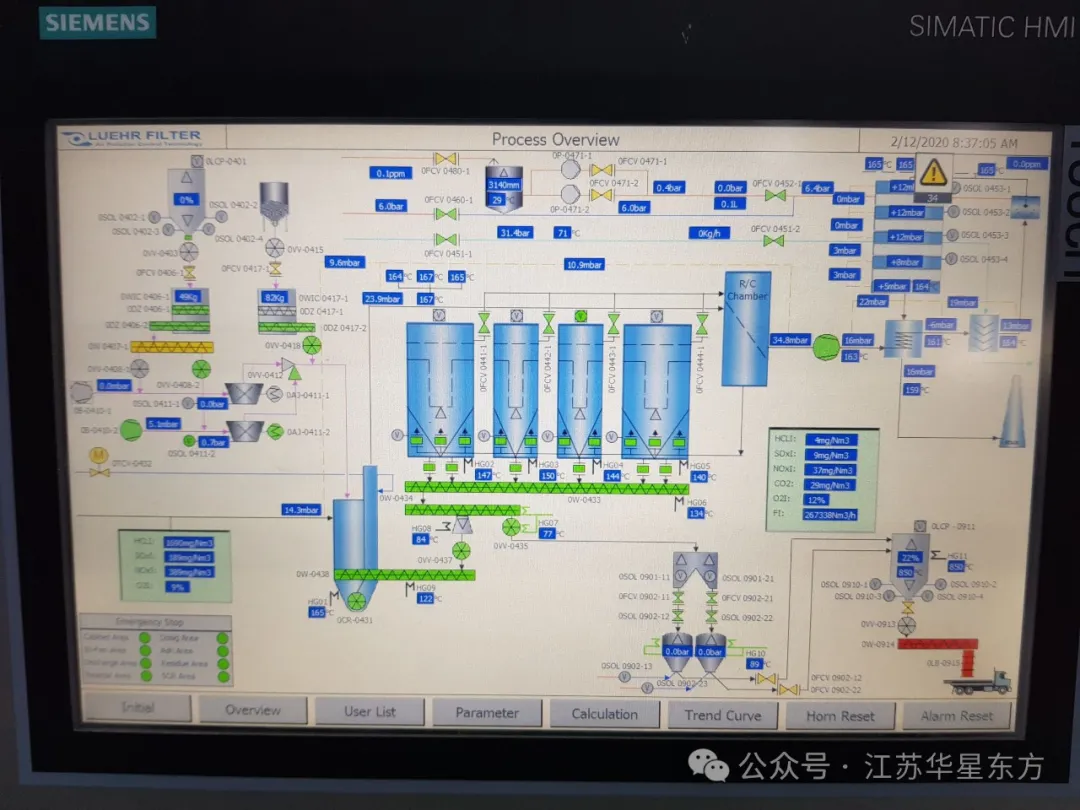

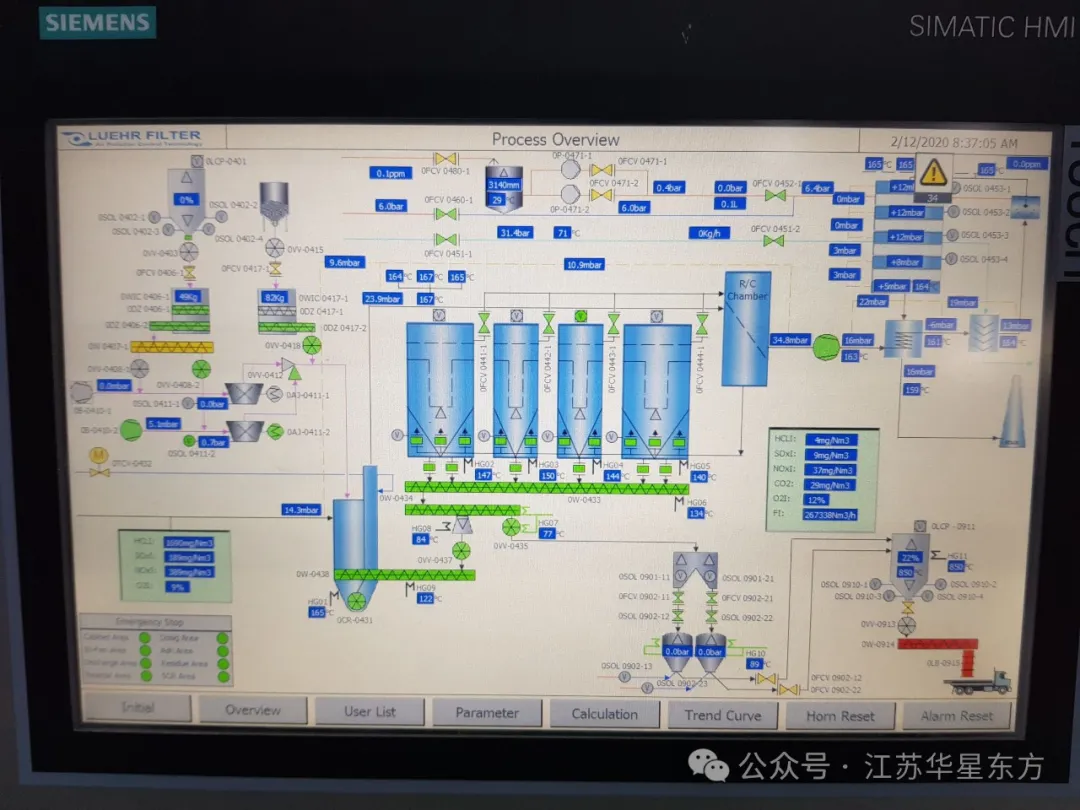

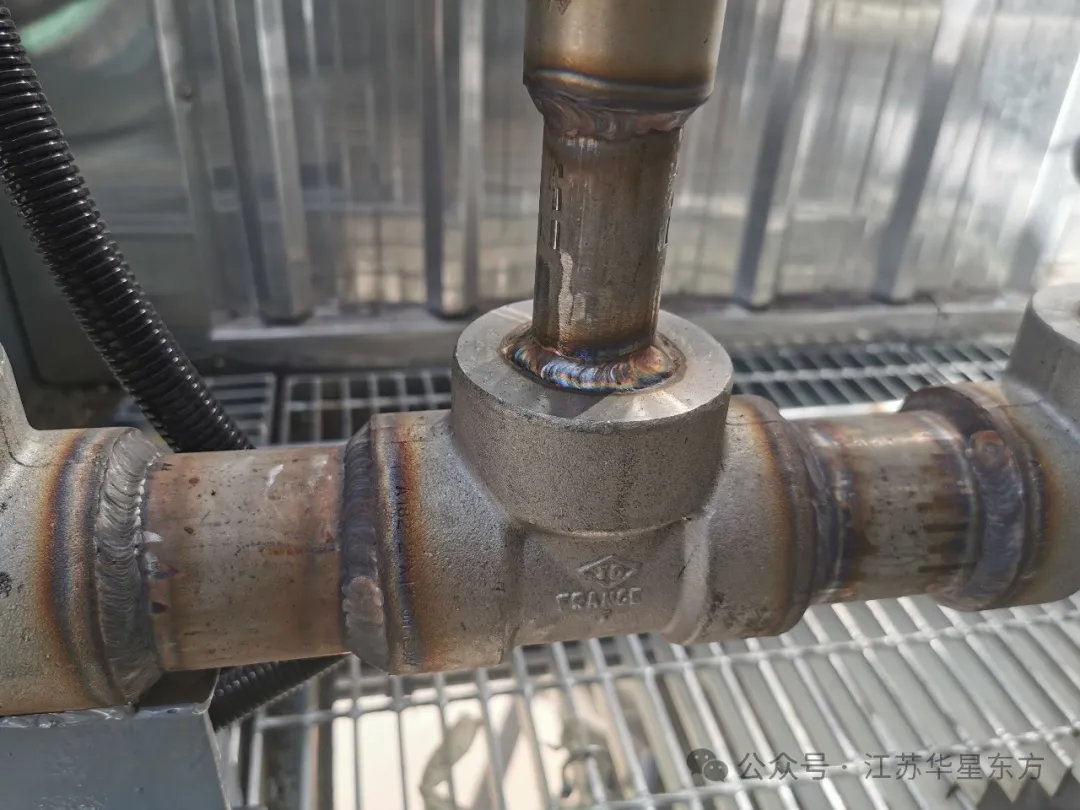

This industrial waste incineration power generation project uses industrial waste, garbage, etc. as the main fuel, with an installed capacity of 8MW. It is located in the Rayong Industrial Zone under the "Eastern Economic Corridor" development plan of the Thai government, adjacent to Lam Chabang Port. Flue gas treatment adopts "high-efficiency dry method (not within the scope of this contract) + bag dust removal (not within the scope of this contract) + fly ash transportation and storage (not within the scope of this contract) + GGH + SGH + SCR + ammonia storage and supply "System" flue gas cleaning process, supply engineering for our company's equipment.

As a regional platform for local industrial upgrading, the "Eastern Economic Corridor" provides more good cooperation opportunities for Chinese companies that are responding to the "Belt and Road" initiative. As China's leading enterprise in the field of environmentally friendly waste incineration flue gas cleaning technology, Huaxing East Co. has actively carried out extensive production capacity cooperation with countries and regions along the Belt and Road, and vigorously expanded overseas markets. Multiple projects have been implemented in Indonesia, Japan, Thailand, Malaysia, India, Turkey and other countries , relying on its strong product advantages and technological advantages, actively deploying expertise and resources on the overseas territory, and striving to become a "Belt and Road" pioneer in energy conservation and environmental protection.

Huaxing East Co’s overseas performance covers: Dundigal City, Telangana State, southern India (rotating spray flue gas cleaning project), Hyderabad, India Phase I and II (SNCR + rotating spray flue gas cleaning project), Vila, Turkey Cardboard factory (circulating fluidized bed flue gas cleaning project), Thailand SCG Group (SCR flue gas cleaning project), GEA Bishoff PTFI MANYAR metal smelting Indonesia project (SDA manufacturing project), GEA Bishoff Norway Boliden, Odda Zinc Smelt project (high temperature Electrostatic + cyclone dust removal project), GEA Bishoff Spanish AC Huelva CirCular Copper Smelt project (high temperature electrostatic + cyclone dust removal project), Indonesia IKS boiler island (flue gas core equipment supply and system process package design), Indonesia TK boiler island (flue gas Core equipment supply and system process package design), Selangor Phase I and Phase II in Malaysia (SNCR + rotary spray flue gas cleaning project), Nishi Nagasaki catalyst supply in Japan, and many other projects.