Service ingenuity—Jiangsu Huaxing East Mitsubishi low-temperature SCR catalyst full life cycle after-sales service

In the era of service economy, service plays an important role in the sustainable development of enterprises. Nowadays, in the field of flue gas cleaning in the environmental protection industry, in addition to core process technology and product manufacturing capabilities, it also promises customers high-quality full life cycle after-sales service, and can actively provide timely and accurate after-sales testing and maintenance support services when problems arise. It is very important to solve customers' problems at the same time.

Jiangsu Huaxing East Co. is an old brand that has been in business for more than 50 years. With the continuous changes in national environmental protection policies and the continuous development of new international processes, it continues to provide customers with dry process, semi-dry process, wet process, SCR, high-efficiency trailblazing carbon-reducing design and other process technology products, and also relies on its complete manufacturing base and R&D center to provide continuous data tracking and after-sales services for the systems and products delivered to customers.

In addition to traditional mechanical conveying, precise metering and feeding, atomizers and electronic control automation and other core equipment maintenance and inspection services, since the first batch of domestic low-temperature SCR (including catalyst) systems were put into operation in 2014, Customers' application of importedow-temperature sulfur-resistantcatalyst technology is alsodeveloping rapidly in China. How to better provide continuous services to users of these catalysts, extend the service life of the catalyst and reduce the generation of hazardous waste have been industry focal points in recent years. After 12 years of Accumulated, Huaxing East Co. has continued to invest hundreds of millions of yuan in this field, completing the construction of production and inspection infrastructure and the implementation of nearly a hundred market projects. Especially in the low-temperature SCR transformation market in recent years, it has gained a leading domestic market share. and is becoming the leader in this market segment.

Anhui Lujiang Phase II Project

Henan Linzhou Project

The Mitsubishi low-temperature SCR catalysts of the Lujiang Phase II project in Anhui (flue gas was put into operation in 2021.8.29 and no catalyst regeneration has been carried out so far) and the Linzhou project in Henan (flue gas was put into operation in 2020.11.28 and no catalyst regeneration has been carried out so far) are about to reach the design service life (24000h). Therefore, the low-temperature catalysts of the above projects need to be inspected for the full life cycle. Final testing is used to diagnose the efficiency and poisoning of the catalyst, thereby assessing whether the current catalyst's performance degradation and degree of poisoning require regeneration or new purchase.

Huaxing East Co. Mitsubishi low-temperature SCR catalyst full life cycle after-sales service team provided free after-sales service to customers as soon as possible, and sent professionally trained after-sales service personnel and provided advanced detection devices in line with industry standards to inspect the low-temperature catalysts for the two projects. Activity is tested.

Lujiang project inspection site

Linzhou project inspection site

Huaxing East Co. after-sales service personnel conducted on-site inspection and analysis of the denitrification efficiency of the Mitsubishi low-temperature SCR catalysts in the two projects during actual use. At the same time, they provided customers with more information on the control logic problems and operational problems of their SCR and SNCR systems. Professional solutions and advice.

Huaxing East Quality Inspection Center

Huaxing East Co. was entrusted by the customer,

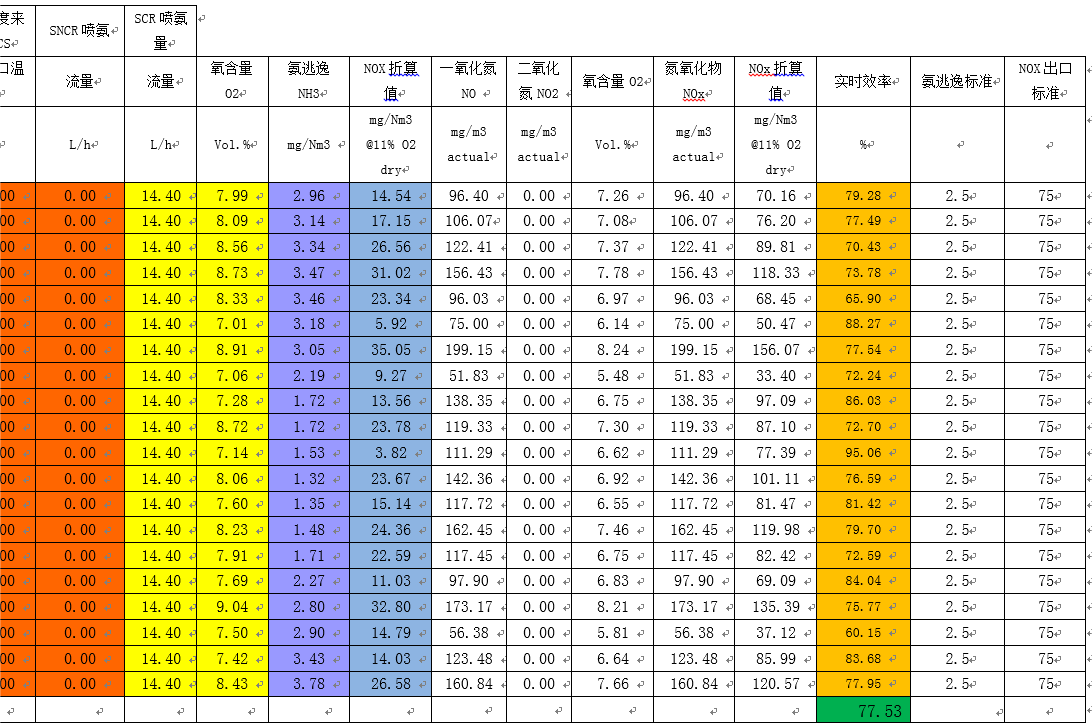

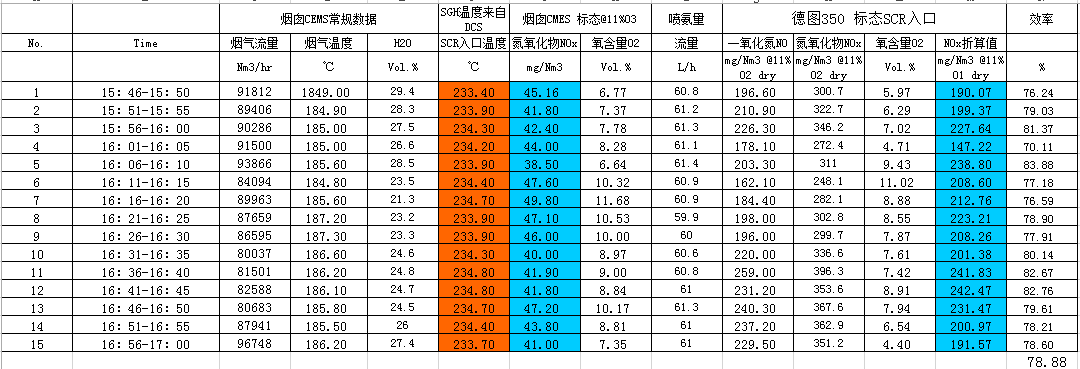

and our Quality Inspection Center (Anhui Zhongyi Manufacturing Platform) conducted a performance evaluation of the denitrification efficiency of the Mitsubishi low-temperature SCR catalyst samples provided by it

The test results show that the low-temperature catalyst denitrification efficiency of the Lujiang project is 77.5% (technical agreement design value: 75.0%); The low-temperature catalyst denitrification efficiency of the Linzhou project is 78% (technical agreement design value: 72.2%). The low-temperature SCR catalysts of both projects comply with the natural decay law of Mitsubishi catalyst's designed ultra long chemical life, which is still within the design margin range and meets the conditions for continued use.

Mitsubishi low-temperature SCR catalyst testing data for Lujiang Phase II project

Linzhou project Mitsubishi low-temperature SCR catalyst testing data

Through this after-sales testing service, it was fully verified that even after the three-year service life of the Mitsubishi low-temperature SCR catalyst sold by Huaxing East Co. has expired, the denitration efficiency of the Mitsubishi low-temperature SCR catalyst is still stably maintained above the standard value, reflecting the excellent performance and quality of this product.

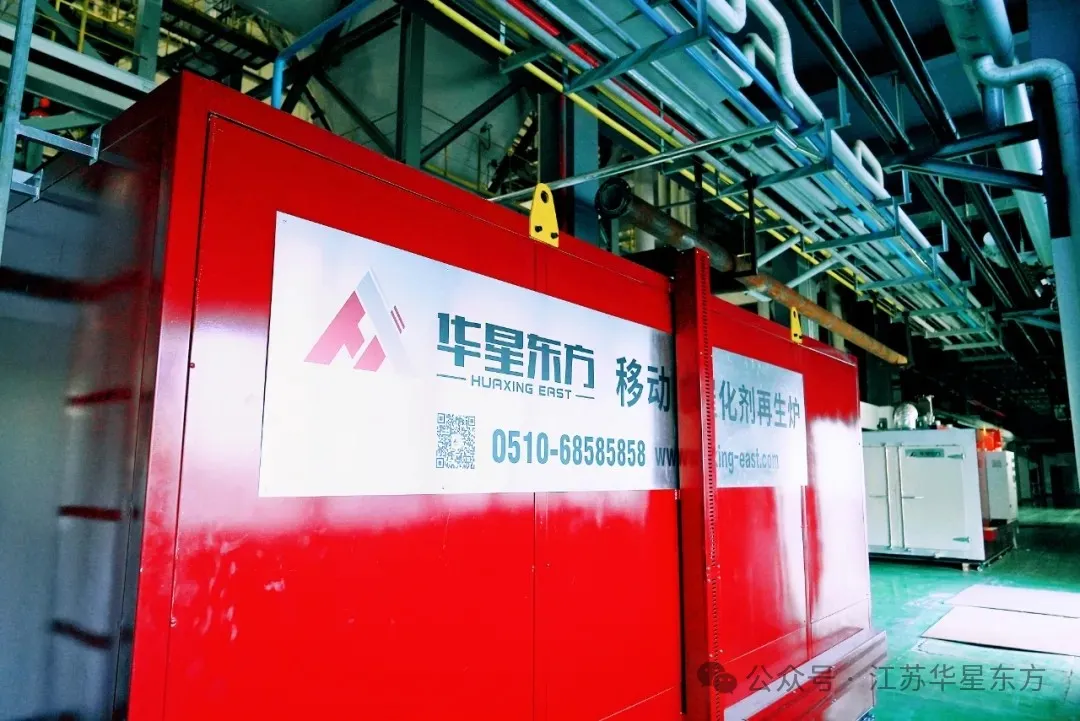

Huaxing East Co. can not only provide customers with after-sales services throughout the life cycle of Mitsubishi low-temperature SCR catalysts, but also provide a complete set of comprehensive solutions including low-temperature catalyst installation control, technical support, movable offline regeneration services, and offline water washing regeneration services plan.

Huaxing East's Co. low-temperature SCR catalyst offline off-site and offline in-situ regeneration systems have been successfully used in dozens of projects in Nanjing, Haiyan, Jiande, Taizhou, Caofeidian, etc.

China Star Oriental SCR's nationwide performance covers: Tianjin Dongli (2400t/d), Shandong Huangdao (2250t/d), Jiangsu Xuzhou (2250t/d), Shaanxi Gaoling (2250t/d), Zhejiang Jinhua (2250t/d) , Zhengzhou (south), Henan (2250t/d), Haikou, Hainan (1950t/d), Cixi, Zhejiang (1500t/d), Linyi, Shandong (1500t/d), Haining, Zhejiang (1500t/d), Lanshan, Shandong (1500t/ d) and nearly 100 achievements.

The low-temperature SCR catalyst performance of Huaxing East Co. and Mitsubishi Heavy Industries in China includes: Shanghai Laogang Phase II (6000t/d), Shenzhen Eastern (5000t/d), Wuhan Qianzishan (1500t/d), Shandong Yanzhou, Ningbo Dong Qiao (1500t/d), Hebei Shijiazhuang (1200t/d), Shaanxi Ankang (1200t/d), Jiangyin Huarui (1000t/d) and other dozens of projects.