我公司承建的湖南省常德市生活垃圾焚烧发电项目三期烟气净化工程于2022年1月6日通过72+24小时试运行。

The flue gas cleaning (FGC) project undertaken by Huaxing for Phase III of Changde waste incineration power plant in Hunan Province passed 72+24 hours trial operation on January 6, 2022.

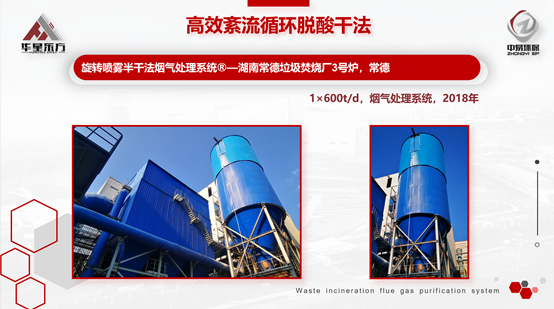

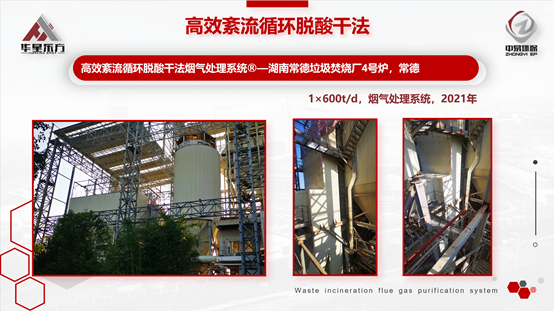

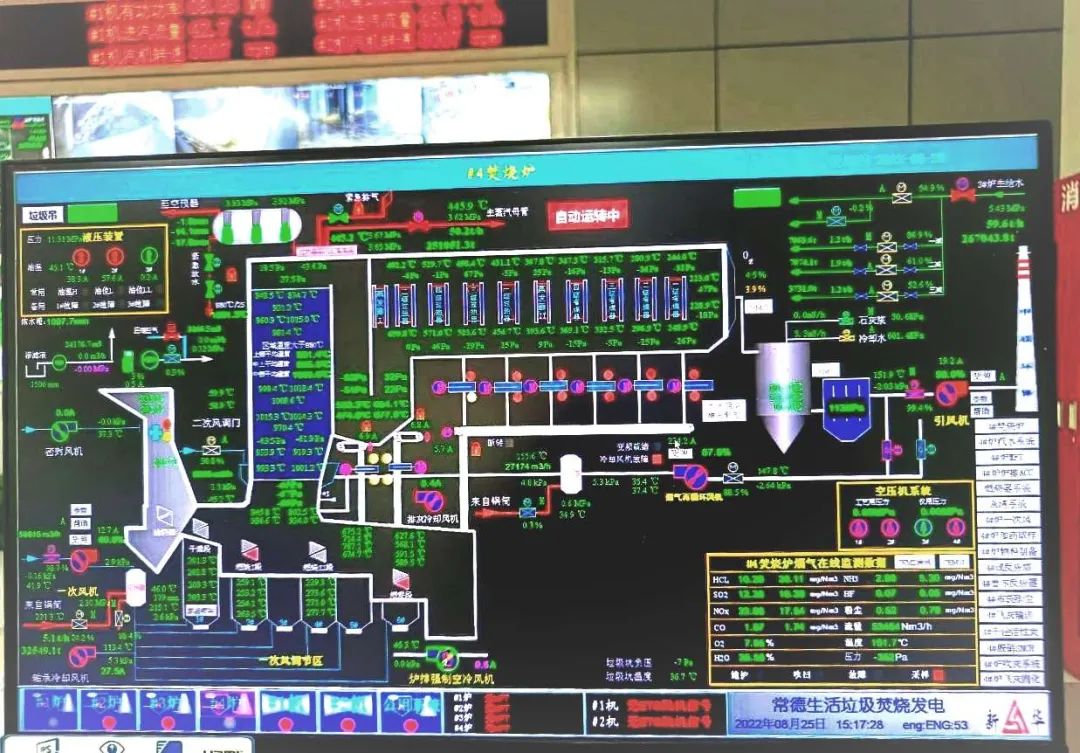

该项目设计规模日焚烧处理垃圾600吨,配 1x600t/d机械炉排式垃圾焚烧炉,配置一套烟气净化系统。烟气净化系统主要用于脱除余热锅炉出口烟气中的颗粒物、酸性物质、重金属等污染物,使其满足本项目规定的排放要求。烟气净化系统采用“炉内SNCR脱硝(尿素)+半干法(Ca(OH)2)+干法(Ca(OH)2)+活性炭喷射吸附+高效紊流循环脱酸干法工艺+袋式除尘(含布袋下返料系统)+SCR(预留)+飞灰输送、储存及稳定化+引风机”组合工艺,并在半干反应塔入口及半干反应塔出口设置烟气在线分析仪,在烟囱入口设置CEMS,实现药剂投加的自动控制,为我司EP工程。

The plant is designed to incinerate 600 tons of municipal solid waste per day, equipped with a 1x600 t/d mechanical grate incinerator and a set of FGC equipment. The FGC system is mainly used to remove particles, acid substances, heavy metals, and other pollutants at the outlet of the waste heat boiler, meeting the emission requirements of the plant. The FGC system adopted the combined process of "SNCR in-furnace denitration with urea + semi dry method with Ca(OH)2 + dry method with Ca(OH)2 + activated carbon injection adsorption + dry method with high-efficiency turbulent circulation deacidification + bag filter with mass-returning + SCR reserved +fly ash conveying, storage, and stabilization+ ID fan”. The flue gas online analyzer is set at the inlet of the semi dry reaction tower and the outlet of the semi dry reaction tower . CEMS is set at the chimney inlet. The automatic control of reagent dosing is realized. It is an EP project of Huaxing.

随着中国焚烧装备逐步走向国际市场,华星东方在参与海外国际交流和竞标活动时,感受到近几年国际主流烟气工艺的趋势正在从半干法、湿法往高效干法转变。特别是华星东方协助国内总包方走出去时遭遇欧美企业较低的锅炉排烟温度而获得的较高锅炉效率,越来越成为中国装备竞标国际项目的短板。

2016年起,为了了解和掌握未来烟气工艺发展的最新走向,华星东方技术团队陆续走访了欧洲部分焚烧厂并与欧洲同行展开了接触与交流,就该工艺的引进进行了接洽。

As China's incineration equipment is gradually moving towards the international market, when participating in international exchanges and bidding activities, Huaxing experienced that the mainstream of flue gas cleaning technology was recently changing from semi-dry / wet method to efficient dry method. In particular, when Huaxing assisted the domestic enterprises to go abroad, the higher boiler efficiency obtained by European and American enterprises due to the lower boiler exhaust gas temperature has increasingly become a weak point for Chinese equipment to bid for international projects.

Since 2016, in order to understand and master the latest trend of future FGC process, the technical team of Huaxing East has successively visited some incineration plants in Europe, carried out basic contacts and communications with European counterparts, and contacted the introduction of the new dry-process.

2017年底,华星东方与欧洲同行首次携手签署了北京高安屯医废项目,率先确立了使用该“高效紊流循环脱酸干法工艺”。

At the end of 2017, Huaxing and its European partner jointly signed the Beijing Gao'antun Medical Waste Project for the first time, taking the lead in establishing the use of the dry-process of "Efficient Turbulent Circulation Deacidification".

2018年华星东方顺利与欧洲同行携手完成了泰国工业固废项目,建立了第一次合作。

In 2018, Huaxing successfully completed the industrial solid waste project in Thailand with its European partner, established the first cooperation.

2019年起,华星东方携手欧洲同行与北控集团北发建设一同将该工艺应用于常德三期生活垃圾焚烧项目,并于2020年开始实施,2021年7月接入烟气,2022年初完成72小时验收。截止发稿为止,该系统已平稳运行1年3个月。

Since 2019, Huaxing East & its European partner and Beifa Construction of Beijing Enterprises Group have applied this process to the Changde Phase III WTE plant. The new dry-process was implemented in 2020. The flue gas was connected in July 2021, and the 72 hours acceptance was completed in early 2022. As of the date of publication, the system has been running smoothly for 1 year and 3 months.

常德3号炉连续一年排放控制数据

1 Year's Continuous Emission Control Data

of Changde No. 3 Boiler

常德4号炉连续一年排放控制数据

1 Year's Continuous Emission Control Data

of Changde No. 4 Boiler

与常德二期传统的SDA工艺相比,其连续周期运行指标基本接近,但石灰消耗量低至5kg/t垃圾,并且省去了制浆系统的投资和运行维护能耗。

Compared with the traditional SDA process in Changde Phase II, its continuous cycle operation index is close, but the lime consumption is as low as 5 kg/ton MSW. The investment in the slurry preparation system and the energy consumption for operation and maintenance are saved.

该项目的意义:

1、解决了物料循环系统在中国烟气含湿率高的炉排炉应用工况下的长期平稳可控运行。自我国引入NID及Turbosorp以来,除极个别炉排和大部分流化床垃圾焚烧炉运行较好,国内显有成功应用案例。华星东方曾参与过,沧州,保定,石家庄等循环干法工艺的SDA技改,包括海口一期,厦门等都出现了系统运行不平稳,烟气含湿率和飞灰潮湿导致返料系统不稳定从而建床失败致使系统运行失败。

2、为小苏打工艺引入,通过物料循环从而减少物料消耗,将SCR往上游移动和外置省煤器+二级活性炭干法和布袋工艺,减少了蒸汽消耗。为超低排放从湿法转向双布袋干法工艺开辟了道路。

3、为原有SDA半干法工艺,在场地受限的情况下增设一道干法进一步实现超低排放提供了解决方案。

4、通过提高SDA半干法排烟温度的控制,增加小苏打物料循环系统结合三菱配方的脱硝布袋及特有的低温再生工艺,为场地极为紧张的旧焚烧厂超低排放改造提供了可能。

The significance of the technology:

1. It solved the long-term stable and controllable operation of the material circulation under the condition of high-moisture grate furnace in China. Since the introduction of NID and Turboprop in China, except for a few grate furnace and most fluidized beds, there are rarely successful applications in China. Huaxing has participated in the SDA technical transformation of the circulating dry process in Cangzhou, Baoding, Shijiazhuang, etc. System operation was unstable in Haikou Phase I, Xiamen. The moisture content in flue gas and fly ash led to the instability of the circulation, which led to the failure of bed formation and the failure of system operation.

2. Sodium bicarbonate is introduced to reduce material consumption through material circulation. SCR is moved upstream and external economizer + two-stage activated carbon dry and bag process are installed to reduce steam consumption. It opens up a way for ultra-low emission from wet process to double-bag dry process.

3. It provides a solution for the original SDA semi-dry process to further achieve ultra-low emissions by adding a dry process under the condition of limited site.

4. By improving the control of SDA semi-dry flue gas exhaust temperature, adding sodium bicarbonate circulation combined with MHI's formula of denitration bag and its unique low-temperature regeneration, it is possible for the ultra-low emission transformation of the old incineration plant with extremely tight site.

华星东方正致力于探索和实践最优的固废烟气治理解决方案,并为行业积累工程应用数据。

Huaxing East is committed to exploring and practicing the best solid waste FGC solutions, and accumulating engineering application data for the industry.

华星东方在湖南省的业绩涵盖包括:常德二期、三期、石门、武冈等多个项目。

The achievements of Huaxing East in Hunan Province include Changde Phase II & III, Shimen, Wugang, etc.