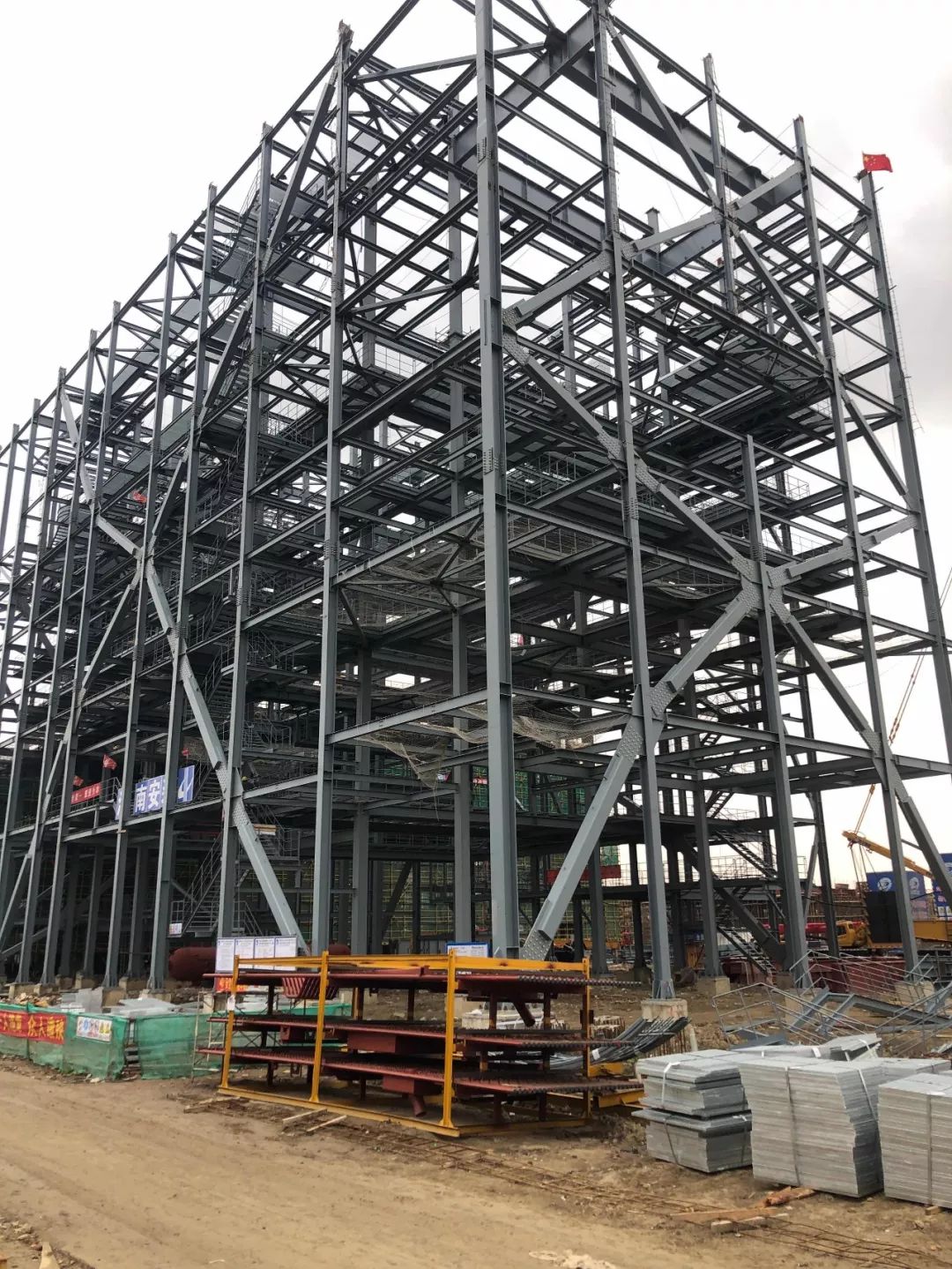

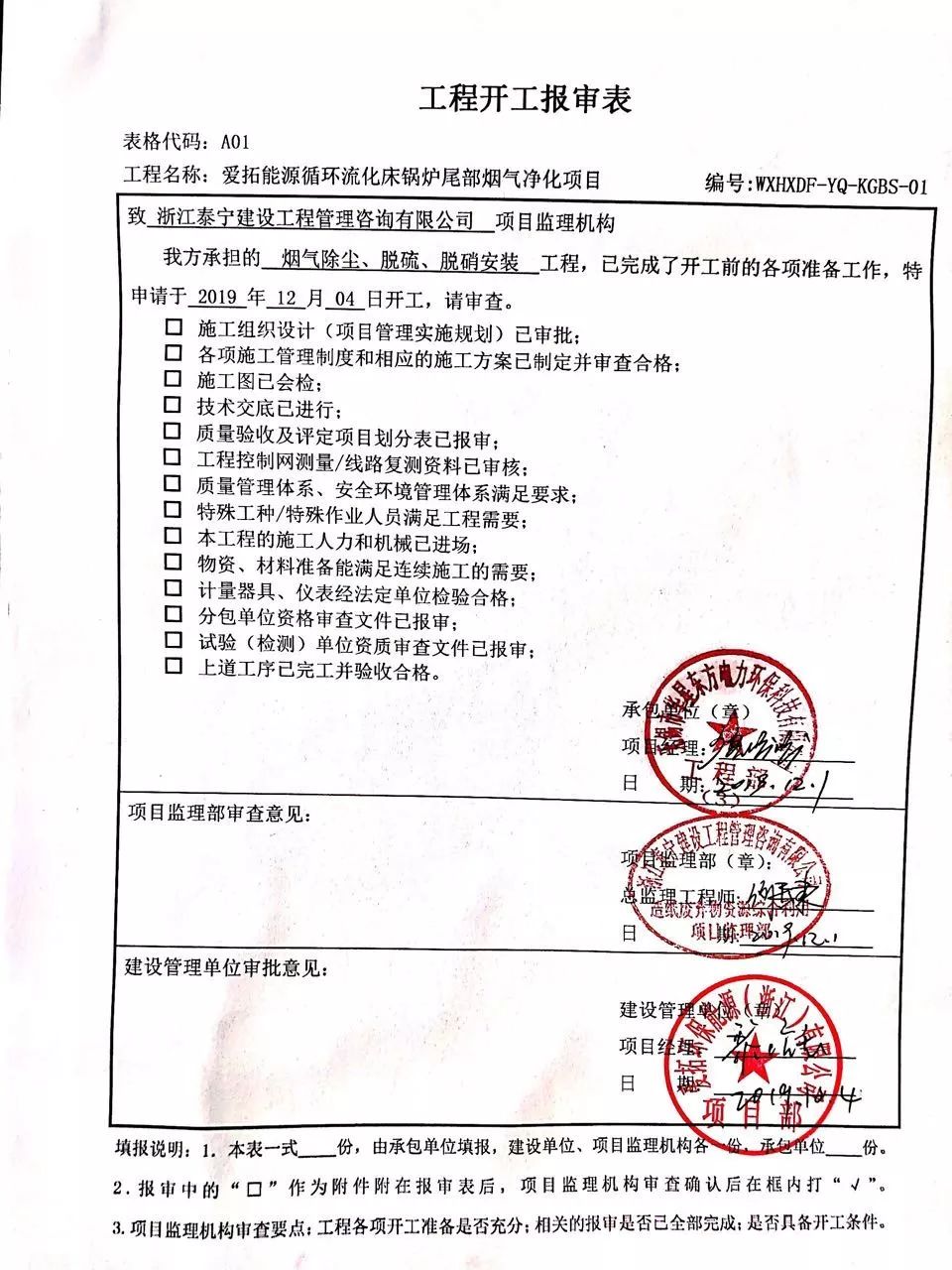

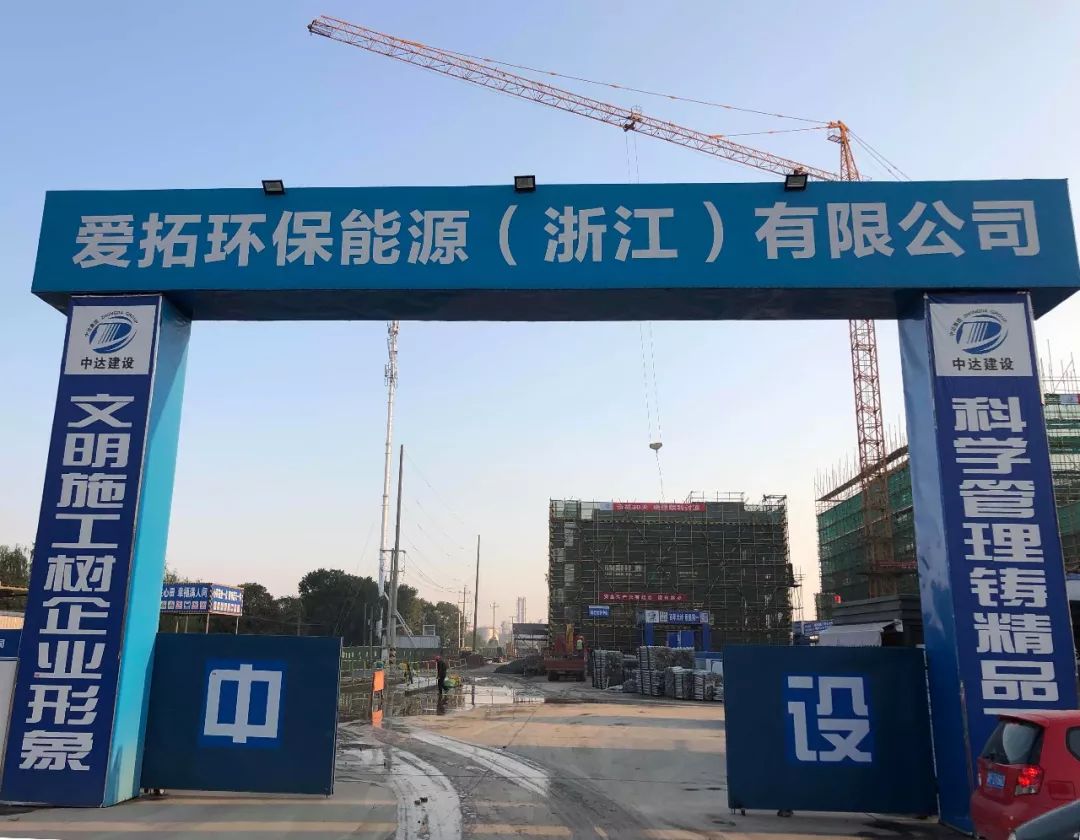

2019年12月4日,爱拓环保能源(浙江)有限公司造纸废弃物资源综合利用项目的烟气净化工程正式开工建设,该工程项目为迄今为止全球单炉处理量最大的固废处理项目,其在行业内具有重要的划时代意义,其比欧洲最大的瑞典Malar垃圾焚烧厂的单炉处理量还要大25%,其对中国乃至国际市场的行业经验和工程数据积累具有重要意义。

The flue gas cleaning system for the paper-making waste resource comprehensive utilization project of Aituo Environmental Protection Energy Co.,Ltd in Zhejiang Province was started its construction officially on December 4, 2019. Having become the world’s largest solid waste process project for single incinerator so far, this project has an epoch-making significance in the related industry. Its single-incinerator treatment capacity is at least 25 percent higher than that of the Malar Waste Incineration Plant in Sweden which is thought as the one having the highest single-incinerator treatment capcity in Europe.

工程整体效果图

Overall Effect Drawing of the Project

该项目采用芬兰Valmet的锅炉,其烟气工程由我司EPC总承包,并协调丹麦Niro共同参与该项目的设计。该项目不同于目前国内千篇一律的套用设计工艺,针对项目的特定边际条件,华星东方与Niro一同为该项目的烟气工艺度身定做了较为适宜的烟气净化工艺。Niro公司由其总工Clause带领团队与华星东方的工程师一起共同完成了项目的工艺设计和数据校核。

This project uses the boilers of Valmet,Finland. Its flue gas cleaning project is contracted by us in the form of EPC and Niro Company of Denmark was invited to jointly design with us for this project. Different from the current projects adopting the stereotyped designing process in China and based on the specific marginal conditions in this project, Huaxing East and Niro Company jointly designed the most suitable flue gas cleaning process for this project. Both the engineers from Niro headed by the Chief Engineer Clause and the engineers from HXET worked together to complete the process design and data verification for the project.

华星东方技术人员在多次出访欧洲交流培训,并通过实施和完成天津青光、张掖、山东高密等类似工艺的工程实践后,与Niro共同合作实施了临淄一期1x1000t/d、二期1x1000t/d之后,再次携手合作实施爱拓环保能源项目。该项目的建成和投产将代表固废行业领域的顶尖水平,为继续推动固废行业烟气治理的工程实践积累宝贵经验。

After they paid multiple visits to Europe where they had received the relevant professional trainings and finished their engineering practices of the similar process in the projects of Tianjing(Qingguang)Municipality City, Zhangye City as well as the projects of Gaomi City in Shangdong Province, the technical staff of HXET cooperated with Niro to complete the constructions of the first & second- stage projects of 1x1000TPD in Linzi City. After so many times projects cooperation, HXET and Niro cooperated again in the Aituo Environmental Protection Energy Project. With the completion and commissioning of this project which represents the top level in the solid waste industry , this project really contributes to the valuable experience accumulation for engineering practice which can help further promote the flue gas treatment in solid waste industry.

丹麦Niro总工Clause先生与其团队与华星东方团队交流设计思路

Mr. Clause, Chief Engineer of Niro, Denmark, along with his team was exchanging design ideas with the HXET technical team.

该项目新建1×2000t/d处理量垃圾焚烧锅炉+1×N50MW汽轮发电机组。烟气处理采用SNCR+炉内喷钙脱酸+静电除尘器除尘+旋转喷雾半干法+消石灰干法喷射+碳酸氢钠喷射+活性炭喷射+袋式除尘+预留低温SCR+飞灰输送、储存及稳定化工艺,为我公司EPC工程。

This project newly built a waste incinerator of 1×2000TPD and a steam turbine generator set of 1×N50MW. Its flue gas treatment adopts the combined processes of SNCR + Limestone Injection Deacidification Inside the Incinerator + ESP Dust Removal + SDA + Slaked Lime Dry Method Injection + Sodium Bicarbonate Injection + Activated Carbon Injection + BHF + Reserved Low Temperature SCR + Fly Ash Transportation, Storage and Stabilization. It is our company’s EPC Project.

该项目的一些新设计思路在于设计烟气净化工艺时,出于对控制飞灰处理成本的考虑,设计有静电预除尘器,在投产后通过飞灰鉴别以期降低飞灰处理成本;在设置预除尘的脱除效率时,考虑了飞灰脱除效率对下游设备的烟气操作露点的影响;在控制雾化器的选型时,考虑了半干法和不同工况的干法选择的运行配比,避免了雾化器选型过大,运行人员难以操作的问题;在设计静电除尘器时,通过张掖,高密等固废领域的投产静电除尘器的工程经验反馈,针对含氯较高的烟气和固废行业普遍存在的飞灰特性恶劣的工况,同时也吸收了丹麦Amager Bakke焚烧厂静电除尘器的一些优化设计,对静电除尘器做了大量的细节调整。

Some new design ideas made in this project are listed as follows:When the FGC process was being designed, an ESP Pre-dedusting was added in order to control the flue gas treatment cost. After the production, the fly ash identification was introduced to reduce the fly ash treatment cost as well. When the removal efficiency of pre-dusting was set, the influence of fly ash removal efficiency on the flue gas operation dew point of the downstream equipment was fully considered.When the model of control atomizer was selected, the operational ratios of Semi-dry Method and Dry Method under different operating conditions were also considered,which can effectively avoid the problems like: the size of atomizer chosen is too large or it is difficult for the staff to operate. When the ESP was designed, a substantial alterations were made based on the feedback from the engineering experiences of the operated ESP used in the solid waste field such as the projects of Zhangye City and Gaomi City. Its design fully considered the feature of flue gas which contains higher chlorine and the working conditions of poor fly ash characteristics prevailing in the solid waste industry. Its design also benefits from some of the optimized designs of ESP operated in Amager Bakke Incineration Plant, Denmark.

目前,该项目正紧锣密鼓地实施推进中,该项目是华星东方2020年的重点工程项目之一,该项目投产后,将与华星东方执行的上海松江二期2x850t/d、成都邓双2x880t/d、南昌3x880t/d、保定二期1x1000t/d、三河2x1000t/d等工程项目一样,为行业积累宝贵的大型锅炉烟气净化工程数据,为中国固废烟气领域的企业走向世界前列积累更多的工程经验。

At present, Huaxing East is stepping up its effort to construct this project. As one of the key projects of HXET in 2020, this project can help accumulate the precious FGC engineering data of big-sized incinerators for the industry and more engineering experience for Chinese enterprises engaged in the flue gas cleaning industry of solid waste to compete internationally, just like what the projects in progress by HXET such as Songjiang Second-stage 2x850TPD, Shanghai Municipality and Dengshuang 2x880TPD,Chengdu Municipality,3x880TPD in Nanchang Municipality, Second-state 1x1000TPD, Baoding City,2x1000TDP,Sanhe City did as before.