我公司承建的山东高密垃圾焚烧发电2x400t/d循环流化床锅炉烟气净化工程于2017年11月9日完成整体竣工验收。

Shandong Gaomi Waste Incineration Power Generation 2x400t/d Circulating Fluidized Bed Boiler we contracted to build has completed its overall construction and acceptance check on November 9, 2O17.

该项目于2016年11月施工建设,2017年1月30日投入运行,同年8月31日整体竣工调试验收结束。该项目为我公司EPC项目,采用静电除尘器+半干法SDA工艺(旋转喷雾半干法)+布袋除尘器+活性炭吸附+干粉喷射+飞灰稳定化处理工艺。

The project was started its construction in November, 2016 and was put into operation on January 30, 2017. The overall construction & debugging work and acceptance check was completed on August 31st of the same year. It is a EPC project of our company, using Electrostatic Cleaner + Semi-dry SDA Process (Rotary Spray Semi-dry Method) +Baghouse Filter, Activated Carbon Absorption+ Dry Powder Jet, Fly Ash Stabilization Treatment Processes.

该工艺针对流化床垃圾炉灰量高、排烟温度低、SOx波动不稳定、灰分差异导致的输送方式不同等特性进行了针对性地工艺调整。早期的流化床垃圾炉,由于煤的掺烧比较高,因此烟气燃烧工况较为平稳。随着国家出台了发电量补贴上限为吨垃圾280度的规定以及煤价上扬带来的成本上升,流化床垃圾炉燃料中煤的掺烧比逐年下降,随之带来的燃烧工况出现了较大的改变。

为此,华星东方工程师与锦江集团技术人员等在实践中不断摸索,陆续在天津晨兴一期,二期,甘肃张掖等项目上进行了工艺改进。

This process is designed to offer a targeted process adjustment for the characteristics of fluidized bed including high ash content, low temperature of flue gas discharge, SOx fluctuation instability, ash composition difference which requires for different transport modes. For the early stage of the fluidized bed waste incinerators, the combustion condition of flue gas is relatively stable due to the high blending burning ratio of coal. Due to the provision the nation has published on the subsidy top-limit for power generation should be 280 degrees per ton of garbage and the uprising cost caused by the rising coal price, the blending burning ratio of coal in the fuels of fluidized bed waste incinerator is decreasing year by year, consequently the combustion condition has a big change.

For this reason, the HXEP engineers, together with the technical staff of Jinjiang Group, are continuously exploring in practice and achieved process improvement in the following projects such as Tianjin Chenxing First Stage & Second Stage and Gansu Zhangye, etc.

天津项目技术探索

Technical Exploration of Tianjing Project

公司工程技术人通过此次山东高密项目的调试,利用积累的工程经验,进行了多次技术优化调整,最终找到了一条适合国内现有流化床垃圾炉运行的先进烟气净化工艺路线,很好地适应了流化床垃圾炉的持续运行和稳定达标排放。

Through the debugging work for the Shandong Gaomi Project, our engineers and technicians took advantage of the accumulated engineering experiences to make a plenty of technical optimization adjustments so that they finally found out an advanced FGC process route which is suitable for the existing operation status of the domestic fluidized bed incinerators. It is well adapted to the continuous operation of fluidized bed waste incinerator and reaches the stable up-to standard emission requirement.

甘肃张掖项目技术探索

Technical Exploration of Gansu Zhangye Project

随着流化床垃圾焚烧技术的不断发展,公司通过不断引进吸收欧洲先进技术工艺,继天津,张掖,高密之后,陆续在山东临淄以及河北石家庄等项目上持续进行工艺改进,不断调整和摸索适合中国流化床垃圾炉工况的烟气净化技术。

With the continuous development of waste incineration technology in fluidized bed , our company constantly introduced a lot of advanced process technologies from Europe to conduct process improvement in the first group of projects such as Tianjing, Zhangye and Gaomi, then further process improvement was made in projects of Shangdong Linzi as well as Hebei Shijiazhuang. In this process ,we have been constantly adjusting and probing for a FGC technology which is suitable for the combustion condition of Chinese fluidized bed waste incinerator.

经过验收,两套烟气净化装置运行工况良好,烟气处理各项指标均低于国标18485-2014标准,同时低于欧盟2000标准。

After having passed the acceptance check, the two FGC lines still have quite good running conditions. Each index of flue gas treatment is lower than the international standard 18485-2014 .It is also lower than the European Standard 2000 at the same time.

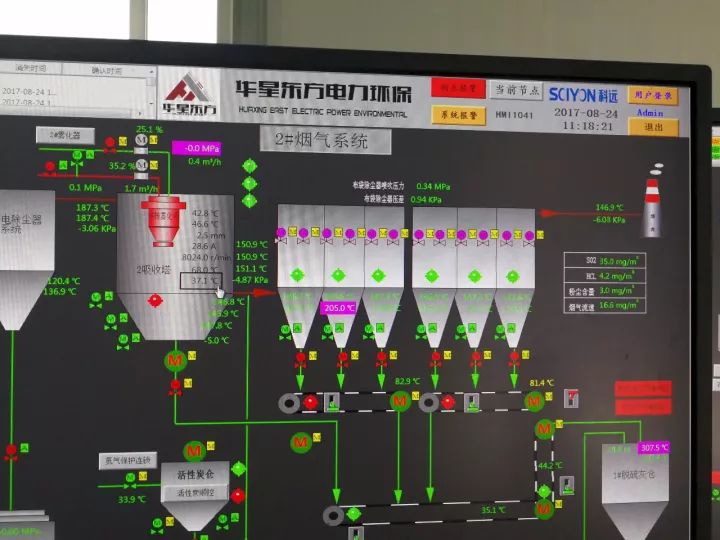

高密上位机截图

The Screenshot of Upper Computer for Gaomi Project